intelligent-Automated Robotics Manufacturing System (i-ARMS)

intelligent-Automated Robotics Manufacturing System (i-ARMS) is our answer to the growing production demands for higher productivity, quicker return on investment, cost savings and real time production monitoring.

What is i-ARMS?

It is an incorporation of multiple innovative technologies such as conveyors, industrial lifters, robots and manufacturing execution system (MES) along with vision systems, sensor devices and RFID that are combined into one powerful factory automation solutions.

Conveyor System

It offers a quick & efficient transportation of loads of in any shapes, sizes and weights from one location to another which can be transported horizontally, vertically, around corners, incline and decline.

- Spiral Conveyor

- Capable of moving at either constant or index speed.

- Operate-able within a small footprint, saving valuable floor space.

- Conveys loads up and down in a continuous flow facilitating high throughputs.

- Requires only a single drive motor which results in substantial savings in energy, controls and systems integration.

- Chain Conveyor

- Capable of carrying products on double, triple or multiple strands of chains.

- Provides good positive drive and is an economical form of transportation of goods.

- Long runs are more economical when compared to any other conveyor styles.

- Belt Conveyor

- Flat continuous conveying surface enables for various shape and sizes products handling.

- Driven by an AC induction gear motor.

- Available in variable speed control.

- Bus Bar Conveyor

- Ideal for assembly, testing and packing of all variants of the product that require power supply applications.

- Supports up to 100kg of product weights.

- Capable of supplying current rating up to 60amps.

- Conveying speed up to 1m/s.

- Gravity & Wheel Conveyor

- Constructed with gravity rollers or wheels for support and movement.

- Operates independently without the need for a drive unit.

- Cost efficient for conveying light weight cartons, trays or totes.

- Power Roller Conveyor

- Proven to be efficient and effective in various industries and applications.

- Saves time and improve efficiency in repetitive load movements.

- Equipped with programmable controls which deactivate zones to save energy and reduce equipment wear and noise.

- Versatile and adjustable to different conditions.

- Slat Conveyor

- Employs a side-flexing plastic chain, allowing horizontal turns and elevation changes within a single continuous run.

- Ideal platform for future expansion or floor re-layout.

- Simplistic Design with minimal components variation.

- Flexible, clean, self-lubricating and low noise.

- Low friction, low maintenance & corrosion-free.

Sortation System

A system that is integrate-able with conveyors to enable products sorting from in-feed main conveyor line to designation shipping lanes, palletizing operations or manual packing stations.

- 90° Belt Transfer

- Available in one direction or Bi-directions.

- Bi-directional unit transfer right and left on command.

- Simple design without any high-wear components.

- Low power consumption (24V DC), providing maximum controls capabilities and dependability.

- Motorized Turntable

- Minimal power usage (24V DC), ensuring robust control capabilities and reliability.

- Available in 90° and 180° curve design.

- Exceptional performance with high efficiency.

- Able to operate in multiple directions.

- Attached Diverter

- Flexible design and easy to install.

- 3-way transfers - Left, Straight and Right.

- Available in 30° SPUR (option available).

- Diverts loads in both single/dual direction.

Industrial Lifters

Our in-house designed lifters are proven with high-speed elevated transfer (up to 2 meter/s) from standard working height to multi-floor height.

- Indexer Lifter

- Driven by AC Brake motor driver, with additional support from 2 right-angle gear heads.

- Multiple cages/platforms to transfer materials up to multiple floors

- Customizable lifter height of 4000mm (max.)

- Multi-indexing flights enable high transfer rate with low-moving speed

- Available with/without infeed and/or discharge conveyor systems

- Motorized Lifter

- Coupled vertical linear actuators, driven by servo motor or AC brake monitor.

- Recommended travel stroke of 5000mm (max.)

- Convertible carrier design, to attach with 90° transfer.

- High UPH: Vertical speed up to 2m/s - servo motor (0.8m/sec AC motor).

- Minimum I/O for easy controls and maintenance.

- Multiple operating levels, with high speed and high accuracy stops.

- Pneumatic Drive Lifter

- Available in C Type, Z Type or 90° Type.

- Driven by Pneumatic actuator.

- Recommended travel stroke of 2000mm (max.)

- Convertible carrier design, to attach with 90° transfer.

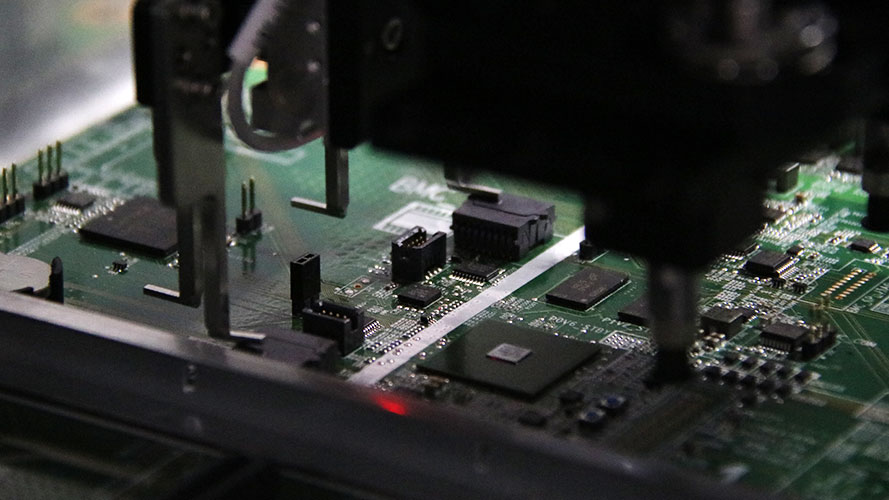

Robotics Technologies

Our extensive robot lineup seamlessly integrates into diverse manufacturing lines and can be combined with cutting-edge sensors and vision imaging technology to enhance functionality.

- Skills & Know-hows

- Parts assembling, material handling, palletizing, packaging and more.

- Integrate-able robots

- SCARA robot, 6-axis robot, collaborative robot, cartesian robot, delta robot.

Automated Guided Vehicle (AGV)

We offer intelligent AGVs with modularity, flexibility, and scalability for efficient material transport in production facilities, warehouses, and distribution centers without requiring manual intervention or permanent conveyor systems.

- PM220 Automated Guided Vehicle

- Payload: 100kg, 300kg and 500kg

- Navigation Method: Magnetic Strip Guidance (MG) / Trackless (TS)

- Available in Standard/Extended/Low Bed Version

- PM221 Forklift Automated Guided Vehicle

- Payload: 100kg

- Lifting Height: 100mm

- Navigation System: Laser-based natural feature navigation

Manufacturing Execution System (MES)

Our proprietary MES system which efficiently monitors the entire manufacturing processes on factory floors, delivering real-time visibility and comprehensive tracking for each individual process.

i-MEX- Real-time monitoring of production processes

- Process report tracking & traceability

- Process flow control

- Paperless work flow

- Analysis of data for better yield, outcome & results

- Interconnected with machines/information/production data

- Integrate-able with any 3rd party hardware/software

Product Assembly

Our industrial robots equipped with end effectors are programmable to execute any specific tasks from picking, placing, welding to assembling with exceptional precision.

- High accuracy and precision single/multi-parts assembling.

- Bowl feeding, flexible feeding, part identification, part sortation, part fastening/joining, force sensing, QA inspection and more.

Products Test and Inspection

We recognize that each product must meet defined performance standards before shipping. To achieve this, we apply our expertise by conducting thorough inspections and testing to ensure compliance with stringent requirements.

- Assembly Quality Inspection

- Dimension Inspection

- Product Presence/Absence Detection

- Performance Test

- Electrical Functional Test

Vision Inspection & Guidance System

Our vision system leverage on advanced sensors, software along with artificial intelligence to perform thorough inspections on your products as they move through assembly lines. By integrating cameras to our robots, it enhances their adaptability to a wide range of products and processes, resulting in increased productivity and reducing material handling or assembly processes.

- Robot guidance

- Small parts inspection and placement guidance

- Quality Inspection

- Increases the flexibility of our robots to adapt in part size, shape and location.

- High speed inspections for defects and anomalies.

Packaging/Boxing

We provide high-speed automated packaging and boxing processes that significantly reduce packaging production time while enhancing the efficiency of production lines across various industries.

- Semiconductor Reel Packaging

- Flow Wrap

- Box Cartoning

- Glove Pouch Packaging

Label Application

Label applicators integrated into production lines maintain consistent and error-free label application, reducing the potential for human errors by minimizing direct worker interaction with the production line.

- Suitable for containers, bottles, boxes and more.

- Applicable to multiple positions on the product.

- Include information like company information, product descriptions, barcodes, retail information, promotional offers etc.

Palletizing

We offer inline palletizing solutions that enhances efficiency, consistency, safety and reduces labor costs, while providing precise inventory management to various industries for large-volumes productions.

- Applicable to boxes & cartons, bottles & cans, consumer goods, industrial parts, pharmaceutical and automotive parts.

- Provides precise and accurate placement of products on pallets.

- Adaptable to different product dimensions and stacking patterns.

- Programmable to create specific stacking patterns and accommodate different products shapes and sizes.